GCMS-TQ8050 NX - Funzionalità

Triple Quadrupole Gas Chromatograph Mass Spectrometer

Enhanced sensitivity enables ultra-trace level analysis

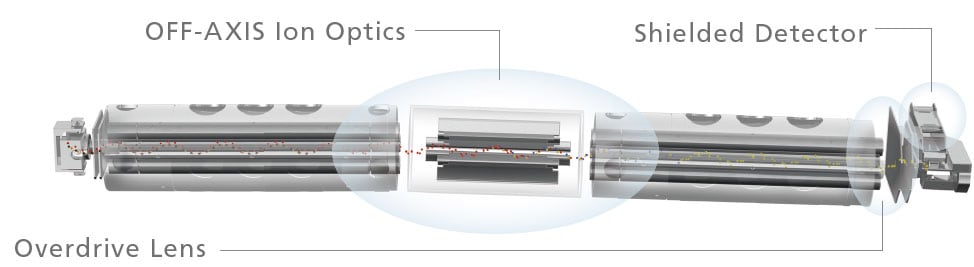

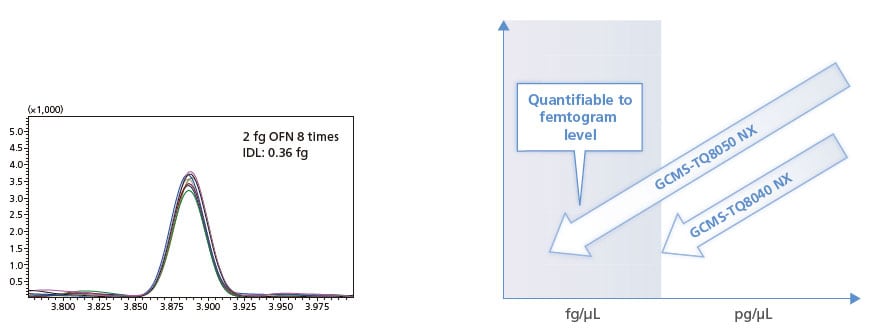

To maximize the benefits of the Off-Axis Ion Optics, the system features three noise-reduction technologies and a detector with improved amplification performance. Due to these state-of-the-art technologies, the system can reliably detect ultra-trace femtogram-level quantities of ions. The resulting exceptional analytical sensitivity and robustness increase the value of solutions and open the door to new applications.

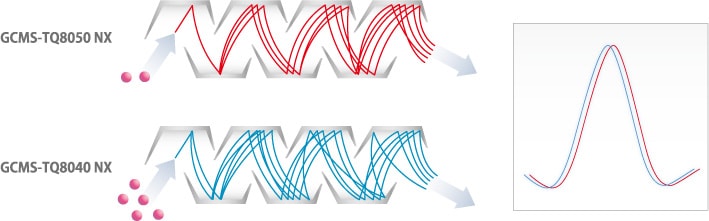

High-Efficiency Detector

The GCMS-TQ8050 NX detects peaks more reliably than the GCMS-TQ8040 NX, even for substances with fewer ions reaching the detector. That means it can reliably analyze femtogram-level concentrations with fewer ions.

OFF-AXIS Ion Optics

The OFF-AXIS Ion Optics eliminate noises such as metastable He ions without compromising sensitivity.

Shielded Detector

Noise from outside the detector was reduced by installing a shield in the secondary electron multiplier.

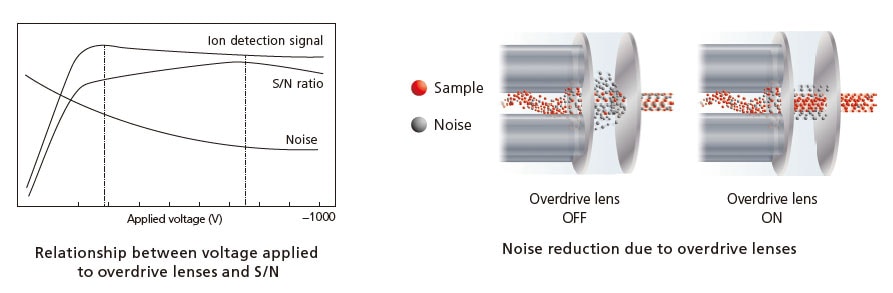

Overdrive Lens

Installing two lenses (overdrive lenses) in front of the electron multiplier reduces random noise from helium or argon and improves S/N. Applying voltage to the lenses improves S/N levels by reducing noise near the lenses and helping to focus the ions that pass through the mass filter (Patent No. US6737644).

The newly designed high-sensitivity detector offers excellent reliability even for samples with femtogram-level concentrations of trace components, achieving sub-femtogram IDL* levels.

*IDL: Instrument Detection Limit

The superior data stability with the GCMS-TQ8050 NX provides sensitivity that rivals high-resolution GC-MS analysis.

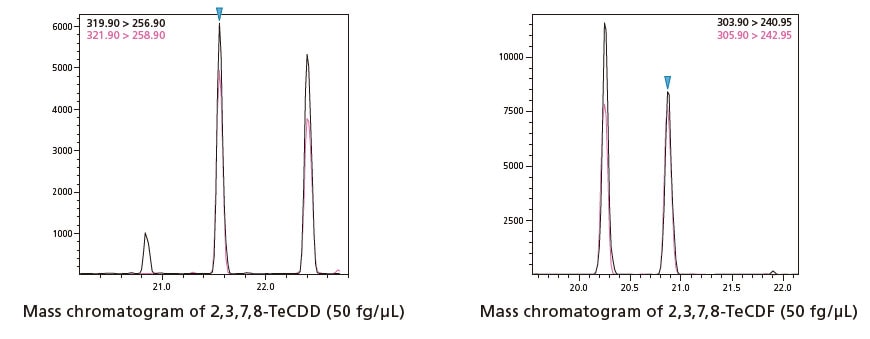

This powerful new analytical instrument reliably identifies peaks even for trace quantities of dioxins and other substances previously considered difficult to analyze using a quadrupole GC-MS system.

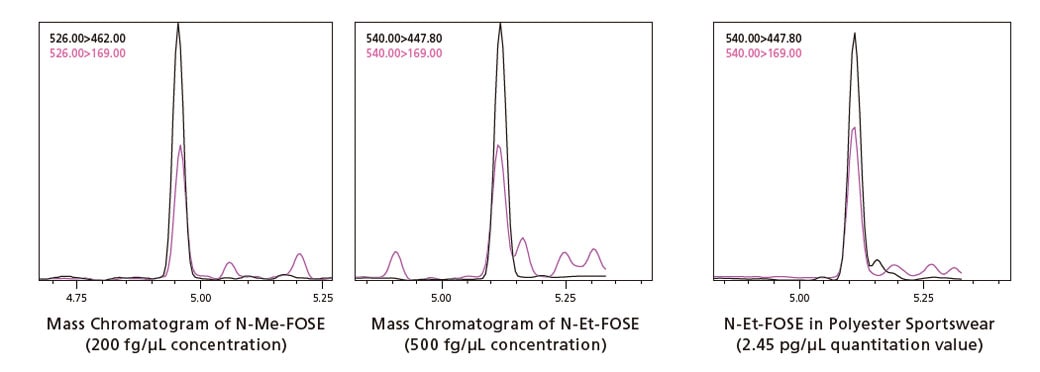

Due to their tendency to resist degradation and remain inside organisms, the use of PFOS, PFOA, and other long-chain perfluorinated chemicals (PFCs) is increasingly being restricted.

Because perfluorooctanesulfonamide and telomer alcohol have been identified as potentially breaking down to PFOS or PFOA, they have attracted attention as compounds that should be monitored in the environment, which involves monitoring trace concentrations.

Simplified user maintenance allows operators to change parts quickly

Active-Time Management™ That Accurately Determines Operation Time

Time Management during Instrument Startup/Shutdown

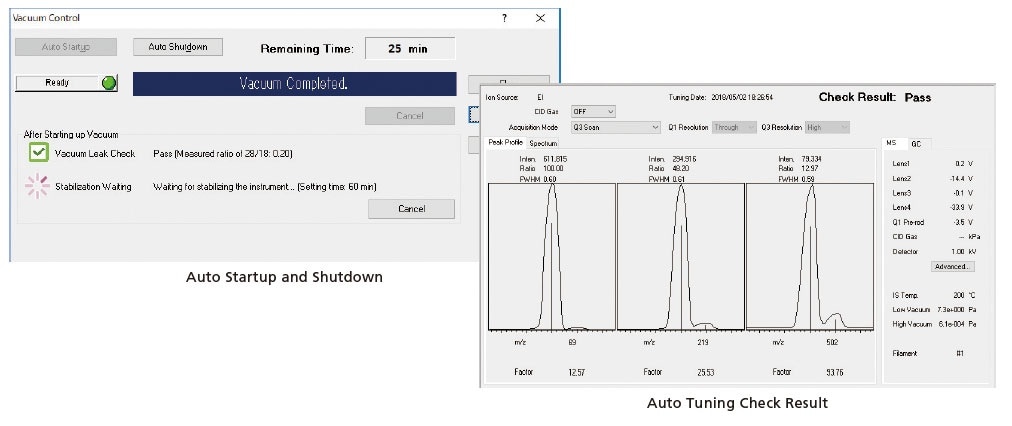

The mass spectrometer has to be operated in a vacuum condition, the startup and stopping of the system takes time depending on the condition. Determining this can be a challenge. Since the amount of time that the system takes when starting up or stopping is displayed in real time, it is easy to accurately determine when maintenance of the ion source or analysis is possible. Moreover, tasks that until now needed to be performed by the user, such as leak checks upon system startup and auto tuning, are now performed automatically.

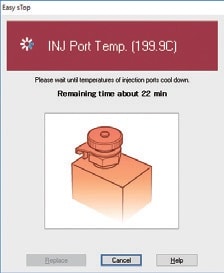

Time Management during Injection Port Maintenance

The Easy sTop function, used to safely maintain the sample injection port without releasing the vacuum, displays the remaining time (coolingdown time) when the septum or the insert can be replaced in real time. Maintenance time can be minimized by understanding the accurate remaining time.

Furthermore, by using a ClickTek nut on the top of the sample injection port, the port can be opened or closed without tools, by simply using fingers to twist a lever. That enables faster and easier insert replacement than ever before.

Easy sTop Function

ClickTek Nut

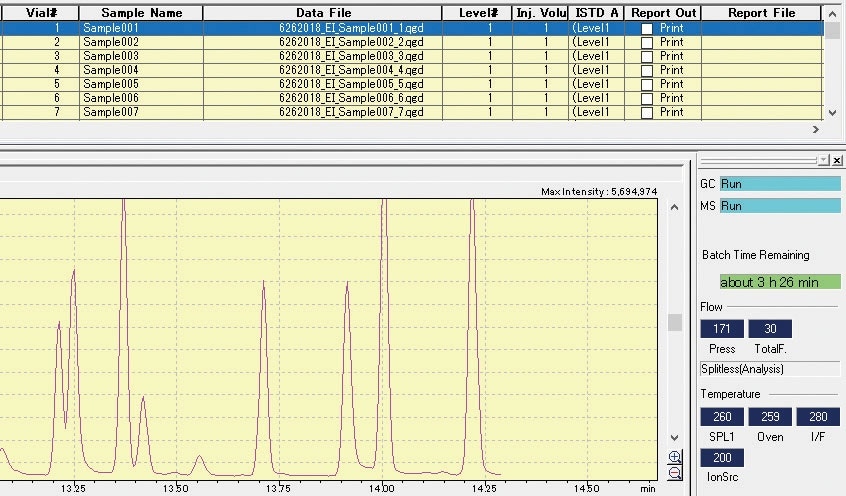

Time Management for Continuous Analysis

By displaying the time required for continuous analysis in real time, the time when the current continuous analysis will finish can be accurately confirmed. This increases the instrument operating time (active time) by reducing standby time required during continuous analysis or while switching between different users. In addition, because this function makes it easier to schedule the timing for analysis preparations, such as sample preparation and pretreatment, based on the finish time of the previous analysis, it enables analytical processes to be performed more efficiently, which can help improve work-life balance.

Time display for continuous analysis can be used only in liquid injection using AOC-20i.

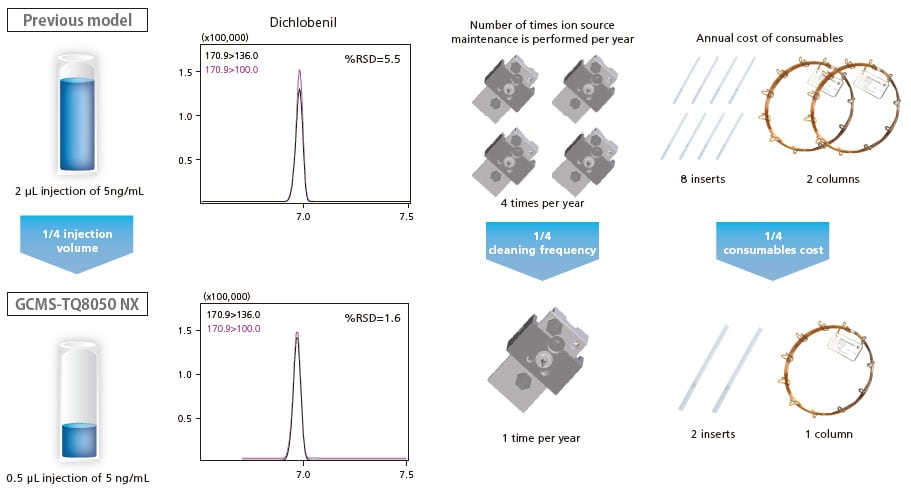

Reduces maintenance frequency and long-term operational costs

In addition to ultra-high sensitivity, the GCMS-TQ8050 NX also offers high robustness. The contamination-resistant ion source and the new detector with over five times longer service life ensure that analysis can be performed reliably for a long time. With the ultra-high-sensitivity performance of the GCMS-TQ8050 NX, injection volumes can be reduced even further than before. The service life of inserts, columns, and other consumables can also be extended to reduce maintenance frequency and costs.

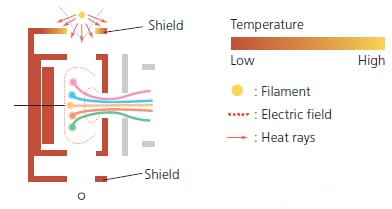

Highly Sensitive and Stable Ion Source

-

The effect of the filament’s electric potential on the ion source is reduced by placing more distance between the filament and ion source box. In addition, a shield blocks out radiant heat generated from the filament to ensure the ion source box temperature remains uniform. Since this prevents any active spots within the ion source, it provides higher sensitivity for analysis. (Patent: US7939810)

High-Performance Quadrupole Mass Filter

The high-accuracy mass filter with pre-rods and patented electric field control technology achieves high-accuracy mass separation performance.

Also, the pre-rods minimize quadrupole contamination and eliminate the need for quadrupole maintenance.

Long-Life Detector

Exhaustive efforts to reduce detector loads during analysis resulted in a significantly longer detector service life. Consequently, the instrument needs to be maintained much less frequently, which results in greater uptime.

Because the GCMS-TQ8050 NX is able to detect ultra-trace ions with high sensitivity, it can also achieve high quantitative accuracy even from trace sample quantities.

Therefore, injection volumes can be reduced during analysis to reduce the analytical loads on the insert, column, ion source, and other parts, and also further reduce maintenance frequency.

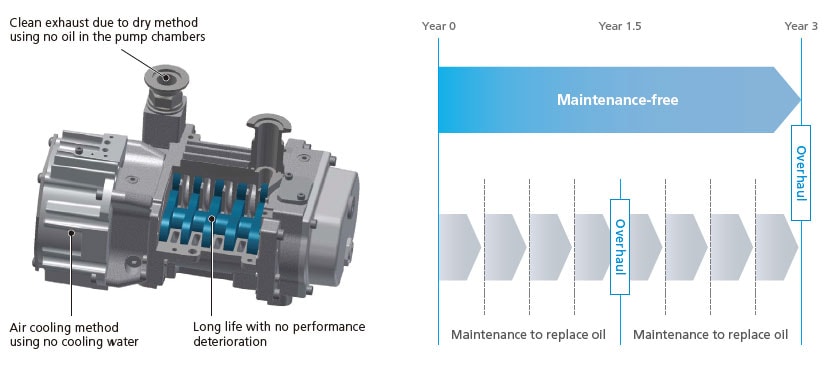

Oil-Free Pump (Optional)

The rotary pump can be replaced with an oil-free pump, which requires no maintenance for three years. This auxiliary vacuum pump not only maintains an oil-free environment inside the vacuum lines, it also eliminates the tedious and time-consuming tasks of replacing and disposing of the oil.